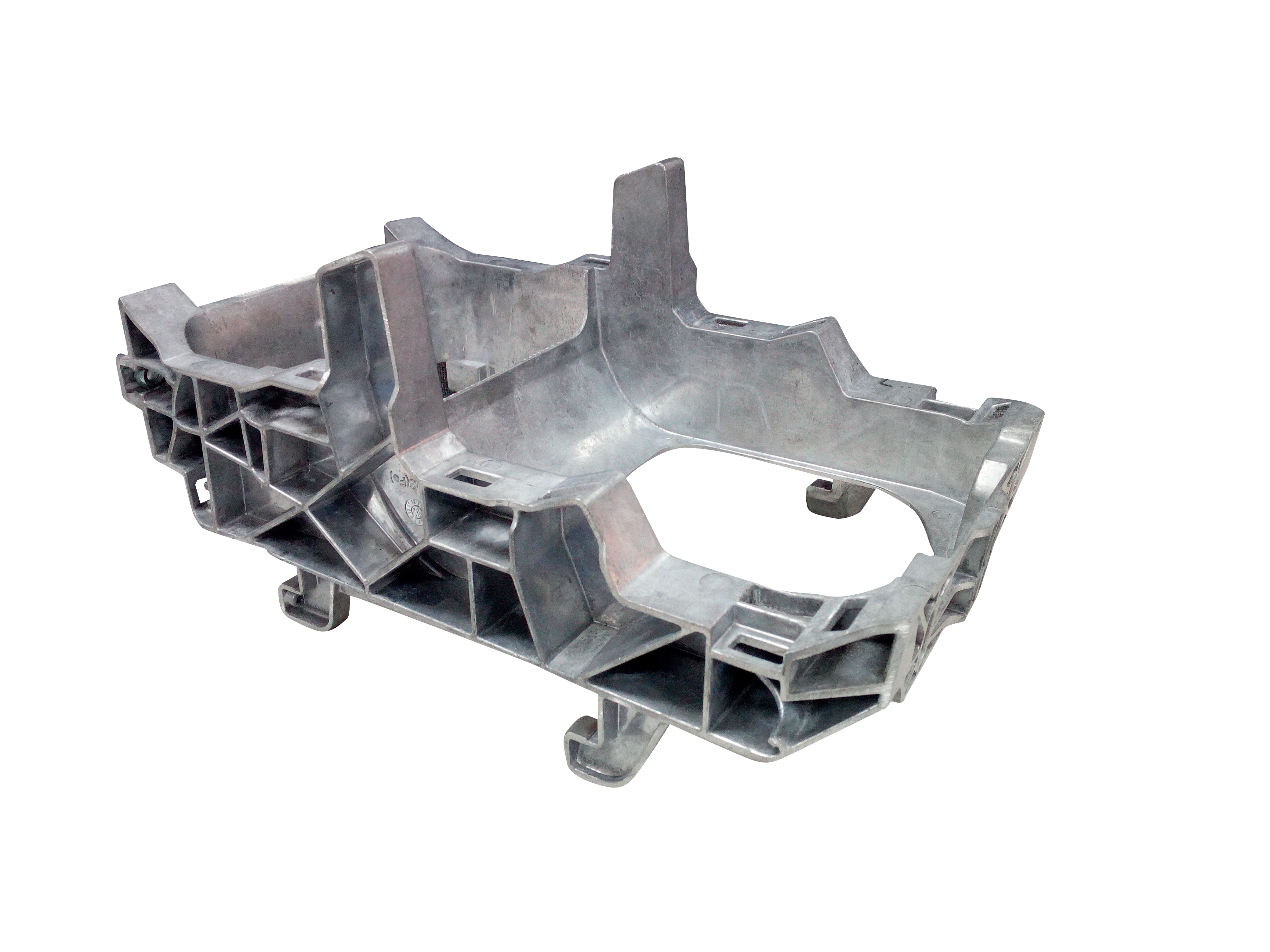

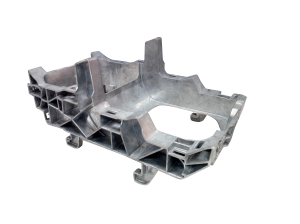

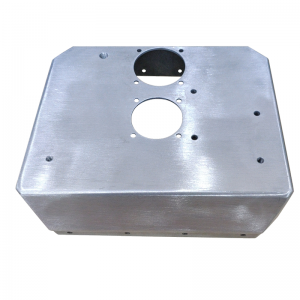

Saldhigga shubka ee aluminiumka cadaadiska sare leh ee qaybaha baabuurta

Faahfaahinta Alaabta

| Habaynta | shubay dice cadaadis sare oo ay sameeyeen mashiinka qolka qabow Jarjarka Dib u soo celinta Qarax rasaas ah Nadiifinta dusha sare Mashiinka CNC, taabasho, rogid Saliidaynta Kormeerka dhammaan cabbirka gaar ahaan cabbirka muhiimka ah |

| Mashiinno | Mashiinka shubka ee Die laga bilaabo 250 ~ 1650tonsMashiinnada CNC 130 qaybood oo ay ku jiraan nooca Brother iyo LGMazakMashiinnada qodista 6 qaybood Mashiinnada tuubada 5 qaybood Khadka saliidda si toos ah u nadiifiya Khadka dahaadhka otomaatiga ah Cidhiidhiga hawada 8 qaybood Khadka dahaadhka budada Spectrometer (falanqaynta walxaha ceeriin) Mashiinka cabbiraadda isku-dubaridka (CMM) Mashiinka raajada X-RAY si loo tijaabiyo daloolka hawada ama daloolada Tijaabiyaha qallafsanaanta Altimeter Tijaabada buufinta milixda |

| Codsiga | Guryaha aluminiumka, kiisaska matoorka, kiisaska baytariga ee baabuurta korontada ku shaqeeya, daboolka aluminiumka, guryaha gearbox iwm. |

| Qaabka faylka la dabaqay | Pro/E, Auto CAD, UG, shaqo adag |

| Waqtiga hogaaminta | 35-60 maalmood caaryada, 15-30 maalmood wax soo saar |

| Suuqa ugu weyn ee dhoofinta | Galbeedka Yurub, Bariga Yurub |

| Faa'iidada shirkadda | 1) ISO 9001, IATF16949, ISO140002) Aqoon-is-weydaarsiyo lagu shubo maydka iyo dahaarka budada oo la leeyahay3) Qalab horumarsan iyo Koox R&D oo heer sare ah4) Hawsha wax soo saarka oo xirfad sare leh5) Noocyo badan oo kala duwan oo ah noocyada wax soo saarka ODM&OEM6) Nidaamka Xakamaynta Tayada Adag |

Habraacyada Wax Soo Saarka Dhuxusha

1. Weydiinta - Hubi in dhammaan shuruudaha ay cad yihiin -->

2. Xigasho ku salaysan sawir 2D iyo 3D ah-->

3. Dalabka Iibka oo la sii daayay-->

4. Arrimaha naqshadeynta iyo wax soo saarka caaryada ayaa la xaqiijiyay--->

5. Samaynta caaryada-->

6. Muunad Qaybeed-->

7. Muunad La Ansixiyay-->

8. Wax soo saar badan--->

9. Bixinta qaybaha

Su'aalaha Inta Badan La Isweydiiyo Ee Ku Saabsan Tuurista Die

1. Waa maxay faraqa u dhexeeya shubka aluminiumka iyo shubka ciidda?

Farqiga ugu muhiimsan ee u dhexeeya shubka meydka iyo shubka ciidda waa maaddada sameynta caaryada. Shubka aluminiumka wuxuu isticmaalaa caaryo laga sameeyay aluminium dahaarka. Dhanka kale, shubka ciidda wuxuu isticmaalaa caaryo laga sameeyay ciid.

Tuurista ciiddu waxay awood u leedahay inay la shaqeyso naqshado aad u adag. Dhanka kale, tuurista meydku waxay bixisaa saxnaan iyo xawaare cabbir badan leh.

Farqi kale oo muhiim ah ayaa ah, shubka ciiddu wuxuu soo saaraa derbiyo qaro weyn halka shubka meydka ah uu soo saari karo derbiyo khafiif ah. Sidaa darteed, shubka ciiddu kuma habboona qaybo yaryar.

Xawaaraha wax soo saarku waa farqi kale oo muhiim ah oo u dhexeeya labada farsamo. Qalabka lagu shubo qalabka ...

Tuurista qalabka birta ah waxay ku habboon tahay wax soo saarka baaxadda weyn sida haddii aad u baahan tahay kumanaan qaybood. Laakiin tuurista ciidda waxay ku habboon tahay wax soo saarka yar yar sida 100-150 unug.

2. Sidee ayuu qaali u yahay shubka aluminiumka?

Tuurista aluminiumku waa mid ka mid ah hababka ugu kharash-oolsan ee loo sameeyo biraha. In kasta oo qalabka lagu sameeyo tuurista miridhku uu u baahan yahay waqti dheeraad ah, haddana waxaad abuuri kartaa kumanaan unug oo leh hal qaab. Inta badan ee aad soo saarto, ayaa qiimaha cutubku yaraanayaa. Aluminiumku aad ayuu uga jaban yahay birta aan miridhku lahayn, wax yarna wuu ka qaalisan yahay birta kaarboonka.

3. Sidee dhakhso ah ayuu u shaqeeyaa habka loo shubay meydka?

Tuurista qalabka dice waa hab shubis otomaatig ah. Waxay qaadataa waqti in la sameeyo qaabka. Laakiin qaabka dice wuxuu si dhakhso ah u adkeyn karaa aluminiumka. Maadaama uu yahay hab otomaatig ah, mashiinku wuxuu soo saari karaa cutubyo badan isagoon wax nasasho ah qaadan. Sidaa darteed, dice waa hab degdeg ah gaar ahaan marka aad soo saarayso tiro badan oo qaybo ah.

Aragtidayada warshadda

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com